Piston Engine Problem

Please select the menu for your specific piston problem.

Piston engine problem - CRACKED

Cracks in the top of a piston (crown) in petrol engines are usually the result of excessive combustion pressure caused by excessive compression or over advanced ignition timing. These conditions cause excessive combustion pressure, which in turn causes the piston crown to crack as the piston is operating outside the pressure it was designed to work under. In diesel engines this damage can be caused by a condition called thermal fatigue.

Thermal fatigue occurs when an engine is consistently operated under full heavy load followed by light load. The constant drastic changes in combustion temperature eventually results in thermal cracks of the piston crown.

Piston skirt cracking is usually a result of constant excessive loading of the engine and high mileage fatigue or in some cases faulty piston design. The manufacturer usually corrects the later by supplying a superseded part.

Incorrect fitting of pistons to rods can cause stress fractures, which develop into serious skirt cracking early in the life of a repaired engine. Piston skirt cracking is not a common engine fault and IS ALMOST TOTALLY ELIMINATED OUT OF MODERN PISTON DESIGN

Cracked ringlands are usually caused in detonation or pre-ignition. Detonation causes excessive combustion temperature and pressure. By design the ring lands are one of the weaker positions on a piston and can crack under this type of stress. The land can completely crack away in sections. Rings will also crack under these conditions.

: Every care has been taken in writing this information and procedures, but no responsibility can be excepted for errors, omissions or misuse of this information and procedures. The information available on this site is for your instruction only and cannot be copied for sale, © copyright 2020 UMR Engines www.engineproblem.com.au

Piston engine problem - PICKED UP

Pistons have 3 main types of skirt pick up or scuffing.

Centre skirt scuffing as the name suggest is usually more prominent on the centre of the thrust skirt of the piston.

The cause is a break down of the lubricant due to a number of possible reasons. These reasons include cooling system failure, lack of lubrication (check con rod squirt holes, excess conrod side clearance, dry assembly) and if the engine fails during running in it could be possible insufficient piston to bore clearance.

Four point scuffing can have a few causes but the most common cause is insufficient piston to bore clearance after rebuild. If the engine has run for many thousands of kilometres and is well out of the run in period the clearance may not be the cause.

Engines running with minimum excepted clearance may experience this failure due to a change in operating temperature, fuel mixture or ignition timing.

In most circumstances this condition is due to insufficient clearance. Under certain conditions it is advisable to increase the clearance by .025m.m.(-001 inch)

All over skirt scuffing has all the same causes as piston / seized (visit piston /seized for more details)

: Every care has been taken in writing this information and procedures, but no responsibility can be excepted for errors, omissions or misuse of this information and procedures. The information available on this site is for your instruction only and cannot be copied for sale, © copyright 2020 UMR Engines www.engineproblem.com.au

Piston engine problem - SEIZED

Seized pistons in an engine that has had no serious overheating problems is usually caused by a breakdown of lubrication.

This can be the final result of rings fitted with insufficient ring back clearance or ring end gap.

If the engine is driven long enough after symptoms start to develop (lack of power, pinging, etc) the result will eventually be piston seizure.

As the friction increases the lubrication breaks down and a complete piston seizure will result in a very short time. If the engine has had a serious overheat the abnormal expansion of pistons and rings in the bore will cause excessive friction and again a breakdown of lubrication will eventually result in an exchange of molten material from the pistons to the bore and visa versa.

As this happens the piston will be permanently seized in the bore.

Items to eliminate as the cause include: ring back clearance, ring end clearance, lubrication, cooling system, piston to bore minimum clearance, severe loading conditions and severe tuning problems. ( retarded, over-advanced, lean mixture.)

: Every care has been taken in writing this information and procedures, but no responsibility can be excepted for errors, omissions or misuse of this information and procedures. The information available on this site is for your instruction only and cannot be copied for sale, © copyright 2020 UMR Engines www.engineproblem.com.au

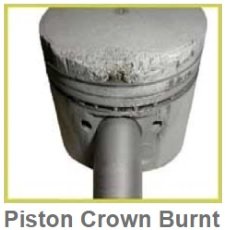

Piston engine problem - BURNT OUT

This is where the outer edge of the crown of the piston is severely eroded. The damage has the appearance of being burnt or exploded away. This damage is the direct result of severe detonation over a long period. In petrol engines the causes for detonation are usually, over advanced ignition timing (base or total advance), compression too high or incorrect octane rating of the fuel.Excessive deposits of carbon or hot spots in the combustion chambers (sharp edges that are thin enough to glow red-hot and cause pre ignition). Incorrect spark plugs, spark cross firing and incorrect air/ fuel ratio can also result in pre ignition.

Diesel engines suffer the same type of damage and is usually caused by faulty injectors, injector pump or pump timing.

: Every care has been taken in writing this information and procedures, but no responsibility can be excepted for errors, omissions or misuse of this information and procedures. The information available on this site is for your instruction only and cannot be copied for sale, © copyright 2020 UMR Engines www.engineproblem.com.au

Piston engine problem - FLOGGED

Visit Piston Picked up / Seize: Every care has been taken in writing this information and procedures, but no responsibility can be excepted for errors, omissions or misuse of this information and procedures. The information available on this site is for your instruction only and cannot be copied for sale, © copyright 2020 UMR Engines www.engineproblem.com.au

Piston engine problem - BROKEN

Smashed or broken pistons are usually the result of another failed engine part. The result of a broken big-end bolt or Conrod generally results in severe piston skirt breakage due to the broken rod contacting the piston at high revs.If the damage is confined to the breakage of the piston pin bosses the cause can be identified by pin seizure in the piston pin boss. Dry assembly and dry starts can cause this failure, even when the pin is freely fitted.

If the damage is concentrated on the crown of the piston it is usually foreign material entering the combustion chamber or a failure of a cylinder head component such as valve or valve seat. Ample evidence can usually be gathered by close examination of the head, carburetor and intake system. Often the failed part may belong to another cylinder but finds its way via the intake manifold. Care must be taken to completely clean all remaining failed components from the intake manifold as they will re-enter the engine on start up and cause the repaired engine to fail. Reconditioned long engines have been destroyed in this manner.

: Every care has been taken in writing this information and procedures, but no responsibility can be excepted for errors, omissions or misuse of this information and procedures. The information available on this site is for your instruction only and cannot be copied for sale, © copyright 2020 UMR Engines www.engineproblem.com.au

Piston engine problem - WORN OUT

Excessive wear on pistons is a normal condition brought about by high mileage and use. Premature wear is usually a result of poor air filtration or lack of service to air cleaners and pre cleaners. Under severe dusty conditions the service interval should be changed so as to maintain good intake filtration at all times. If the damage occurs soon after an engine rebuild the oil should be checked for abrasive contamination from cylinder honing. This is the most common cause for pre mature piston skirt wear following a rebuild. The other main problem following a rebuild is a damaged or faulty intake system. Check all components of the intake system, especially on vans and forward control vehicles where the induction system includes a system of flexible hoses.Quite often the flexible hose is overlooked and was faulty causing the problem in the first instance.

When airborne contamination is the cause the rings will usually be more worn than the piston skirt. When the contamination is an abrasive in the oil the ring and skirt wear will both be very severe and usually over a much shorter period. A good indicator of abrasive oil contamination from honing is when the oil expander rails are worn down to the expander and the expander is making contact with the bore. This damage will normally occur within the first 1000 kilometers.

: Every care has been taken in writing this information and procedures, but no responsibility can be excepted for errors, omissions or misuse of this information and procedures. The information available on this site is for your instruction only and cannot be copied for sale, © copyright 2020 UMR Engines www.engineproblem.com.au

Piston engine problem - HOLE

If the damage is concentrated on the crown of the piston it is usually foreign material entering the combustion chamber or a failure of a cylinder head component such as valve or valve seat. Ample evidence can usually be gathered by close examination of the head, carburettor and intake system.

Often the failed part may belong to another cylinder but finds its way via the intake manifold.

Detonation or pre-ignition is the other cause. In petrol engines the causes for detonation are usually, over advanced ignition timing (base or total advance), compression too high or incorrect octane rating of the fuel.

Excessive deposits of carbon or hot spots in the combustion chambers (sharp edges that are thin enough to glow red-hot and cause pre ignition). Incorrect spark plugs, spark cross firing and incorrect air/ fuel ratio can also can result in pre ignition. Diesel engines suffer the same type of damage and is usually caused by faulty injectors, injector pump or pump timing.

: Every care has been taken in writing this information and procedures, but no responsibility can be excepted for errors, omissions or misuse of this information and procedures. The information available on this site is for your instruction only and cannot be copied for sale, © copyright 2020 UMR Engines www.engineproblem.com.au